Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

#1

Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Need some help guys! For weeks! I've been trying to find out what size to print these damn overlays!!! And its driving me NUTS!!!

Do any of you know the correct size to print these overlay. . ..? I'm using Photoshop and I'm just trying to get the right size so I donít end up spending $45 on eBay!!! Thanx in advance fam. . .

Overlay 1

http://www.bfranker.badz28.com/fbody...Lights_new.jpg

Overlay 2

http://www.bfranker.badz28.com/fbody...CPlate_new.jpg

Overlay 3

http://www.bfranker.badz28.com/fbody...ifter93-96.jpg

Main page

http://www.bfranker.badz28.com/fbody/overlays.htm

Do any of you know the correct size to print these overlay. . ..? I'm using Photoshop and I'm just trying to get the right size so I donít end up spending $45 on eBay!!! Thanx in advance fam. . .

Overlay 1

http://www.bfranker.badz28.com/fbody...Lights_new.jpg

Overlay 2

http://www.bfranker.badz28.com/fbody...CPlate_new.jpg

Overlay 3

http://www.bfranker.badz28.com/fbody...ifter93-96.jpg

Main page

http://www.bfranker.badz28.com/fbody/overlays.htm

#3

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Ok, I do this stuff ALL the time in photoshop, it is really easy if you use my method. What you need is a ruler/tape measure, calculator, and maybe a piece of paper.

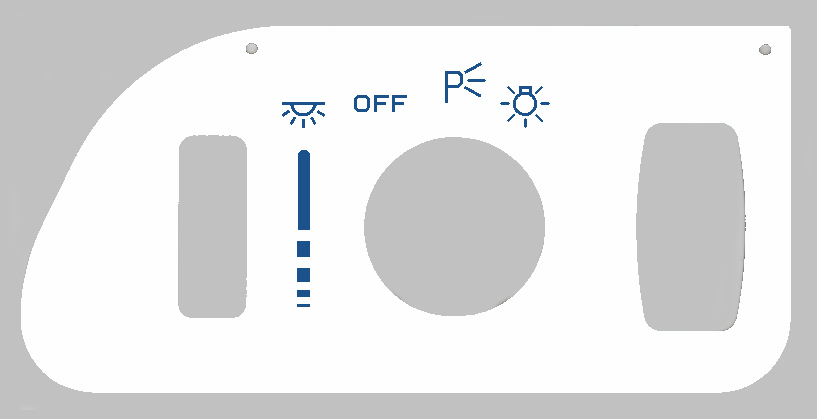

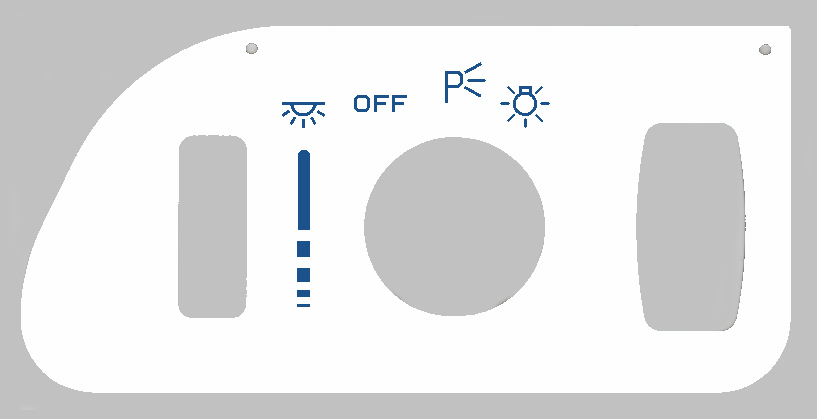

1. use the measure tool in photoshop (it is an alternate tool underneath the eyedropper button) to measure something easy to measure on the picture. Such as the diameter of the circle for the light switch in this overlay:

Make sure you hold down the SHIFT key while measuring, so the line stays perfectly flat and not angled or your measurement will be off.

Make sure you hold down the SHIFT key while measuring, so the line stays perfectly flat and not angled or your measurement will be off.

2. Write down the distance the measure tool says it is (you may need to switch your units/measurements into inches mode... I forgot how to do that, but it's in Photoshop preferences or something).

3. measure the REAL piece in your car with your ruler. Use the calculator if you need to convert 1 and 3/16 inches or something to decimal form... which would be like what.... 1.2 or something? Hell if I know, I'm an advertising major.

4. Divide the numbers to get the percentage. For example, let's say the actual diameter of the real piece was 1.65 inches and the one in the picture was 1.34 inches. That means your overlay is too small, and needs to be bigger, but by how much? Well, 1.65/1.34 would be something like 1.2. Move the decimal point over 2 spaces and you get 120... therefore the overlay would need to be resized to be 120% it's original size to be the size that would fit on the real piece.

5. If you want to be positive about your calculations, check them on the calculator. Ex: 1.34 * 1.2 = 1.6 or something. Make sure to use the calculator and use as many digits as you can, don't round off in your calculations.

Let me know if that helps. I used the same method to make some CAMARO inserts out of wood for an art project, and they'd actually fit on the car... if I wanted wooden inserts

1. use the measure tool in photoshop (it is an alternate tool underneath the eyedropper button) to measure something easy to measure on the picture. Such as the diameter of the circle for the light switch in this overlay:

Make sure you hold down the SHIFT key while measuring, so the line stays perfectly flat and not angled or your measurement will be off.

Make sure you hold down the SHIFT key while measuring, so the line stays perfectly flat and not angled or your measurement will be off.2. Write down the distance the measure tool says it is (you may need to switch your units/measurements into inches mode... I forgot how to do that, but it's in Photoshop preferences or something).

3. measure the REAL piece in your car with your ruler. Use the calculator if you need to convert 1 and 3/16 inches or something to decimal form... which would be like what.... 1.2 or something? Hell if I know, I'm an advertising major.

4. Divide the numbers to get the percentage. For example, let's say the actual diameter of the real piece was 1.65 inches and the one in the picture was 1.34 inches. That means your overlay is too small, and needs to be bigger, but by how much? Well, 1.65/1.34 would be something like 1.2. Move the decimal point over 2 spaces and you get 120... therefore the overlay would need to be resized to be 120% it's original size to be the size that would fit on the real piece.

5. If you want to be positive about your calculations, check them on the calculator. Ex: 1.34 * 1.2 = 1.6 or something. Make sure to use the calculator and use as many digits as you can, don't round off in your calculations.

Let me know if that helps. I used the same method to make some CAMARO inserts out of wood for an art project, and they'd actually fit on the car... if I wanted wooden inserts

#5

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Hmm... it depends on whether or not you want to do it at home or not. Personally, if I was going to go through all that trouble, I'd take the finished (resized) pictures to a printing place on a CD-R or USB flashdrive. I can't think of any specific company names, but a lot of places can do magazine quality or photographic quality stuff alot better than an ink-jet printer at home. And it probably wouldn't cost you more than a dollar or two per copy. If you want to do it at home, I guess use photographic glossy paper and wait for it to dry forever.

I bet if you took it to a printing place, they could print it on some kind of cool plastic or something really high quality. That's what I recommend.

I bet if you took it to a printing place, they could print it on some kind of cool plastic or something really high quality. That's what I recommend.

#6

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Better than that is the method I used to do the gauges in my Mazda.

Take the original and import it into Illustrator or some other vector graphics program. From there, you can draw out all the markings with the shape tools. That way when you print it out in the end, you get crisp, clean lines, no pixellation, and no imperfections from the original scan.

Here's the finished product

Take the original and import it into Illustrator or some other vector graphics program. From there, you can draw out all the markings with the shape tools. That way when you print it out in the end, you get crisp, clean lines, no pixellation, and no imperfections from the original scan.

Here's the finished product

#7

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

The only thing that I see as a problem with doing this is that regular glossy paper won't allow the light to shine through. I've wanted to do something like this for awhile, and I suckered into buying overlays off ebay. It's on a glossy paper, and the light doesn't shine through at all. I bought mine from wholesale_dealzzz or something like that, horrible guy to deal with.. quality of his products, pricing, and payment options were all substandard. But that's not the topic of this thread.

Back on topic, rereading your statement Brangeta about taking it somewhere that does magazine quality stuff, I think magazine-type paper would be thin enough to allow the light through. Then again, it might be so thin that you'd see right through the page, not sure. If someone could figure out a way to solve the issue with light shining through, I'd do this in a heartbeat -- Brent's site has a lot of cool overlays.

Edit: Cajun -- Does yours light through? Do you have any night pics? Those gauges look awesome!

Back on topic, rereading your statement Brangeta about taking it somewhere that does magazine quality stuff, I think magazine-type paper would be thin enough to allow the light through. Then again, it might be so thin that you'd see right through the page, not sure. If someone could figure out a way to solve the issue with light shining through, I'd do this in a heartbeat -- Brent's site has a lot of cool overlays.

Edit: Cajun -- Does yours light through? Do you have any night pics? Those gauges look awesome!

#8

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

CajunCC-- That's a pretty good method, but depending on how you scan the stuff, it can be a completely different size when you print it... I think 200 dpi is life-size and 300dpi is 68% bigger than life-size(or some other weird percentage). I did that for putting new button labels on my cell phone since my original ones rubbed off, and I scanned them in at 300dpi and had to spend a long time calculating the difference.

meissenation- good point, I forgot the light has to shine through. Hmm... there is a type of paper called "Vellum" that is semi-transparent (AKA translucent -- like one of those 'fogged' looking shower doors) that is used for printing wedding invitations. The kind I have is about as thick as 2 pieces of printing/copy paper and you can definitely see through it; but I think the wedding stuff is a lot thicker. I've actually seen it used for business cards, so there is definitely a thick type. We use the sheet type at school when making ads and using the light tables, so it is kind of like tracing paper, but a lot thicker, and less likely to tear.

I'm really not sure exactly what to tell him to do... Is using vellum paper and leaving the stock sticker-things on the car, and just putting the newly printed things over them, out of the question? Or would the switches not be able to turn?

meissenation- good point, I forgot the light has to shine through. Hmm... there is a type of paper called "Vellum" that is semi-transparent (AKA translucent -- like one of those 'fogged' looking shower doors) that is used for printing wedding invitations. The kind I have is about as thick as 2 pieces of printing/copy paper and you can definitely see through it; but I think the wedding stuff is a lot thicker. I've actually seen it used for business cards, so there is definitely a thick type. We use the sheet type at school when making ads and using the light tables, so it is kind of like tracing paper, but a lot thicker, and less likely to tear.

I'm really not sure exactly what to tell him to do... Is using vellum paper and leaving the stock sticker-things on the car, and just putting the newly printed things over them, out of the question? Or would the switches not be able to turn?

#9

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

if it's thicker than three pieces of regular printer paper, there *might* be a very slight problem, otherwise I don't think switches will be a problem. My overlay is a glossy paper that's semi thick, and the switches turn no problem.

#10

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

For mine, i totally replaced the stock gauge faces. The replacements were printed on matte-finish heavy card stock. I gutted the factory backlighting and tapped the wiring to put three white LEDs in the hood over the gauges, lighting them from the front. I'll see if I can dig up night pics, but it basically looks the same as during the day. There's no backlighting at all. I loved it to death. SO easy to read during the day and at night.

Also, factory needles were orange. I scraped the orange coating off the back and painted them black. If i had to do it over again, i would gently sand the whole needle and paint the whole thing flat black instead of just the back of it. The shiny face of the clear needle reflected light from the LEDs. It was a bit annoying at first, but not enough to make me want to take the thing apart again. Heh.

One huge advantage to doing it this way is if you don't like what you design, you can tweak it and make a new set for the cost of paper and ink. The downside is that after a couple years, the paper WILL start to turn a tad yellow. Not really noticeable, but when i replaced a set i had in there for a long time, I could tell the difference holding them side-by-side.

Also, factory needles were orange. I scraped the orange coating off the back and painted them black. If i had to do it over again, i would gently sand the whole needle and paint the whole thing flat black instead of just the back of it. The shiny face of the clear needle reflected light from the LEDs. It was a bit annoying at first, but not enough to make me want to take the thing apart again. Heh.

One huge advantage to doing it this way is if you don't like what you design, you can tweak it and make a new set for the cost of paper and ink. The downside is that after a couple years, the paper WILL start to turn a tad yellow. Not really noticeable, but when i replaced a set i had in there for a long time, I could tell the difference holding them side-by-side.

#11

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Originally Posted by Brangeta

CajunCC-- That's a pretty good method, but depending on how you scan the stuff, it can be a completely different size when you print it... I think 200 dpi is life-size and 300dpi is 68% bigger than life-size(or some other weird percentage). I did that for putting new button labels on my cell phone since my original ones rubbed off, and I scanned them in at 300dpi and had to spend a long time calculating the difference.

#12

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

I may have a solution, but do not know how well it would work! I accidently used the wrong technique in trying to get the red tint of my overlays so my blue leds could shine through my HVAC and this is what happened......

This is what happened with rubbing alcohol! I imagine if you get some sandpaper, mineral spirits, or laquor thinner you'd be able to completely remove all the color from that piece of plastic! or at least the area where you want light to shine through. THen you get your "overlay" printed out on some sort of paper and place it on there!

This is what happened with rubbing alcohol! I imagine if you get some sandpaper, mineral spirits, or laquor thinner you'd be able to completely remove all the color from that piece of plastic! or at least the area where you want light to shine through. THen you get your "overlay" printed out on some sort of paper and place it on there!

#14

Re: Damn Overlays Is Drivin Me Nuts!!!!!!!!!!!!!!!

Hmm... that pictures reminds me of a tip.

Make sure, if possible (depends on the program) that when making stuff, make sure "anti-aliased" is checked in the options. Anti-aliased prevents jagged edges (especially look at the MAX and A/C text, it's really jagged, and definitely not anti-aliased). Also, whenever possible, create vector graphics on this type of stuff, like in Adobe Illustrator or Jasc Paint Shop Pro (though Jasc PSP isn't made for producing print stuff... or at least my old *** version isn't). That way, when or if it is resized, it won't get pixelated.

Also, I talked to someone about using a printing company, and they said that you should make sure to save the files in TIFF or EPS format so there isn't any compression and the printing company will be able to do a good job. Oh yeah; it also needs to be in CMYK mode, not RGB.

Make sure, if possible (depends on the program) that when making stuff, make sure "anti-aliased" is checked in the options. Anti-aliased prevents jagged edges (especially look at the MAX and A/C text, it's really jagged, and definitely not anti-aliased). Also, whenever possible, create vector graphics on this type of stuff, like in Adobe Illustrator or Jasc Paint Shop Pro (though Jasc PSP isn't made for producing print stuff... or at least my old *** version isn't). That way, when or if it is resized, it won't get pixelated.

Also, I talked to someone about using a printing company, and they said that you should make sure to save the files in TIFF or EPS format so there isn't any compression and the printing company will be able to do a good job. Oh yeah; it also needs to be in CMYK mode, not RGB.

Thread

Thread Starter

Forum

Replies

Last Post

tdigger9899

General 1967-2002 F-Body Tech

9

09-07-2015 10:56 AM

cmsmith

2010 - 2015 Camaro News, Sightings, Pictures, and Multimedia

0

07-05-2015 07:23 PM