Fuel/Ignition survey thread plus question about setup

#1

Fuel/Ignition survey thread plus question about setup

Im building a blower motor for my 96 Impala SS. You guys in your light *** F bodies may think it's pointless to do in a 4100 pound car (BEFORE all the blower stuff), but thats just my thing lol. This car is going to see tons of street use, almost daily driven (short ride to work though) and track use as well.

Anyway, the bottom end im planning to build will be tweaked from my existing N/A 396. Callies 3.875 4340 compstar crank, eagle 4340 H beam rods (5.85"), 4 bolt splayed caps. Working on finding an off the shelf piston to lower the c/r down a bit, im shooting for looow as in 8.0-8.5 range.

Cylinder heads I hope to use are advanced induction 200cc ported f body castings but I may end up sticking to my LE2 heads from my N/A motor. Depends on if I get any good offers for the LE2's

Blower is a D1SC, i'll be buying a nice, big intercooler on ebay. I figure I could either go small and expensive such as ATI's 3 core, or just buy something freaking huge for cheaper and hopefully make up the difference with size. I have a lot of room on this car.

Im shooting for 600ish rwhp through a th400. I wouldn't mind making less in the street at lower boost numbers with a larger pulley but when im ***** out at the track, 600whp or more is my goal. How do you guys suppose the eagle H beams and callies compstar will hold up to this? How about the block? With the power needed to drive the blower, the power zapped from the th400 im guessing the parts and fuel system need to handle a good 800hp?

Heres where I run into many different options. Fuel system and ignition. The impala guys have their ideas but I figured i'd come here to see some more.

At the nose end, im going to run 4 12AN fittings into the rails, two at the front top and two in the rear sticking straight out. A 12AN feed line will Y out sending lines to the front top of the rail. Two 12AN return lines will feed to an aeromotive fuel pressure regulator and a 10AN line will run back to the tank as a return line. 83# injectors will be used with an impedance conversion box spliced in to each injector.

The tank side is where I run into problems. A few people have suggested running two 255lph pumps Y'd off in the tank. I thought it would be easier to run 1 external inline pump but the Impalas tank is plastic so I have no way of welding a sump in. I thought maybe just tapping the tank at the lowest point, sending that to the inline pump and then connecting the pump by extending the stock fuel pump harness. Then just run the return to the top of the tank. Heres where I can use any advice on what has been done/what has worked for high power blower motors. Im open to hear any options but I prefer the simplest/cheapest ones that have been PROVEN to work. Im not looking for a dyno queen, this car will see track use and possibly high speed highway blasts (of course, I close the freeway off for this). The car will see real world load so I don't want to be starved in the high end. Keep in mind that my turbo400 is eating a lot more power than the T56's a lot of F body guys run.

Ignition system. Here we go. I know from experience that stock optis don't like high rpm's, and spark also seems to scatter at high rpm's with aftermarket ignition boxes. I shouldn't be seeing high rpm's though with this blower motor, surely nothing over 6500 if that. Obviously I will need a retard box and some kind of spark arrest rev limiter and colder plugs. As far as the rest goes though, what has worked for you guys and what hasn't? Is there away to get the stock opti to provide enough spark for a blower motor?

Lastly, exhaust. A friend of mine at the shop I work at builds some good headers. I plan to have him help me build some step up headers from my old 1/5ths flowtech longtubes. Im wondering if 1 3/4's final primary size will be enough or if i should go larger. Also wondering if a 3" exhaust is going to cause too much heat or if i should go larger? Don't want high EGT's under any conditions. Tires are the only thing I want this motor melting.

Any constructive criticism of anything involved is well appreciated and of course, if you are running a high power, built blower/turbo motor it would be great if you can list what you chose for your fuel system and ignition system. How do you like it? How much power is it supporting? ect...

thanks!

Anyway, the bottom end im planning to build will be tweaked from my existing N/A 396. Callies 3.875 4340 compstar crank, eagle 4340 H beam rods (5.85"), 4 bolt splayed caps. Working on finding an off the shelf piston to lower the c/r down a bit, im shooting for looow as in 8.0-8.5 range.

Cylinder heads I hope to use are advanced induction 200cc ported f body castings but I may end up sticking to my LE2 heads from my N/A motor. Depends on if I get any good offers for the LE2's

Blower is a D1SC, i'll be buying a nice, big intercooler on ebay. I figure I could either go small and expensive such as ATI's 3 core, or just buy something freaking huge for cheaper and hopefully make up the difference with size. I have a lot of room on this car.

Im shooting for 600ish rwhp through a th400. I wouldn't mind making less in the street at lower boost numbers with a larger pulley but when im ***** out at the track, 600whp or more is my goal. How do you guys suppose the eagle H beams and callies compstar will hold up to this? How about the block? With the power needed to drive the blower, the power zapped from the th400 im guessing the parts and fuel system need to handle a good 800hp?

Heres where I run into many different options. Fuel system and ignition. The impala guys have their ideas but I figured i'd come here to see some more.

At the nose end, im going to run 4 12AN fittings into the rails, two at the front top and two in the rear sticking straight out. A 12AN feed line will Y out sending lines to the front top of the rail. Two 12AN return lines will feed to an aeromotive fuel pressure regulator and a 10AN line will run back to the tank as a return line. 83# injectors will be used with an impedance conversion box spliced in to each injector.

The tank side is where I run into problems. A few people have suggested running two 255lph pumps Y'd off in the tank. I thought it would be easier to run 1 external inline pump but the Impalas tank is plastic so I have no way of welding a sump in. I thought maybe just tapping the tank at the lowest point, sending that to the inline pump and then connecting the pump by extending the stock fuel pump harness. Then just run the return to the top of the tank. Heres where I can use any advice on what has been done/what has worked for high power blower motors. Im open to hear any options but I prefer the simplest/cheapest ones that have been PROVEN to work. Im not looking for a dyno queen, this car will see track use and possibly high speed highway blasts (of course, I close the freeway off for this). The car will see real world load so I don't want to be starved in the high end. Keep in mind that my turbo400 is eating a lot more power than the T56's a lot of F body guys run.

Ignition system. Here we go. I know from experience that stock optis don't like high rpm's, and spark also seems to scatter at high rpm's with aftermarket ignition boxes. I shouldn't be seeing high rpm's though with this blower motor, surely nothing over 6500 if that. Obviously I will need a retard box and some kind of spark arrest rev limiter and colder plugs. As far as the rest goes though, what has worked for you guys and what hasn't? Is there away to get the stock opti to provide enough spark for a blower motor?

Lastly, exhaust. A friend of mine at the shop I work at builds some good headers. I plan to have him help me build some step up headers from my old 1/5ths flowtech longtubes. Im wondering if 1 3/4's final primary size will be enough or if i should go larger. Also wondering if a 3" exhaust is going to cause too much heat or if i should go larger? Don't want high EGT's under any conditions. Tires are the only thing I want this motor melting.

Any constructive criticism of anything involved is well appreciated and of course, if you are running a high power, built blower/turbo motor it would be great if you can list what you chose for your fuel system and ignition system. How do you like it? How much power is it supporting? ect...

thanks!

Last edited by SSandman; 03-17-2008 at 01:38 PM.

#2

Well I'm going to help you with what I can. First if you want to upgrade your fuel lines, you only need to go to an -8 line, not 12, and dual intake pumps w/ one on a hobbs switch (turns the second pump on at X amt of boost). Second, you really dont need an ignition box, just gap the plugs around .030 and use something like a TR6 or equivalent. You dont need huge primaries on the headers, 1-3/4 will be enough, 3" crossover pipes will be good, but the downpipe of the turbo go as big as possible.

#3

The reason I figured 12an line is because of the actual internal diameter when including the internal rubber hose... If it was a stainless line, I certainly wouldn't need something that big. I know I have seen F bodies making the power numbers I am after with 10AN braided hose but 8 worries me. As mentioned above, it is a blower car so I need to factor in that 100hp that it may take to drive the blower that wont be showing up on a dyno. Not to mention the turbo 400, 600whp would have a BSFC of a 800-850fwhp motor if my calculations are right. I want to leave room for a conservative tune as well and I don't want to lean out under load be it at the race track or on highway blasts in the top end. If I wish to swap pullies, maybe try to make more power one day (if the bottom end can even handle it) then I want to overdo the fuel system. I am aware that a larger line could put more stress on the fuel pump too, but I have a few good tuning sources that have recommended it. Of course, if you can show me some proof of guys making the kind of power I am after with an 8AN or 10 AN line then I am all for it. I should say that I have no experience with forced induction. I've always been a nitrous guy and I knew next to nothing about setting a motor up for forced induction till I began planning this project a few months ago. With that said, im open to opinions from all those who have done it before, I really am humble but I still like to analyze everything till I am satisfied.

I am not familiar with running two pumps on a hobbs switch, but it sounds like a great idea. Are there any risks of the second pump not turning on soon enough? I guess you'd just set it to turn on a bit early? Probably a great idea to not have two pumps running while puttering around town at under 3500rpm's all day. How would I mount/route and wire two pumps like that though? Using two in tank pumps y'd off or what?

thanks for your reply!!!

I am not familiar with running two pumps on a hobbs switch, but it sounds like a great idea. Are there any risks of the second pump not turning on soon enough? I guess you'd just set it to turn on a bit early? Probably a great idea to not have two pumps running while puttering around town at under 3500rpm's all day. How would I mount/route and wire two pumps like that though? Using two in tank pumps y'd off or what?

thanks for your reply!!!

Last edited by SSandman; 03-17-2008 at 02:58 PM.

#4

here's a DIY for the dual pumps http://ls1tech.com/forums/showthread.php?t=856954

read up on ls1tech, a lot of ppl use the dual tanks, it's what I'm going to be running also

read up on ls1tech, a lot of ppl use the dual tanks, it's what I'm going to be running also

#5

Thanks! Great thread! Im going to have to read that over carefully, especially the part about the wire harness and one way check valve. Of course that will mostly depend on what brand pumps I chose.

Last edited by SSandman; 03-17-2008 at 05:09 PM.

#6

780 rwhp widh a lose converter, fuel was a 50/50 mix of E85/pump gas, beacuse of the E85 the engine needs moore fuel then normal so if it was only gasoline it delivered fuel for 900 rwhp, on top of this we also had a wet 100shot N2O.

This widh 2 parallel walbro inline pumps and a AN8 fuel hose.

Gonna run straight E85 this year and im not worried about the AN8 fuel line, the part im gonna upgrade is pump and add a feedline to each fuelrail insted of the stock crossover line.

This widh 2 parallel walbro inline pumps and a AN8 fuel hose.

Gonna run straight E85 this year and im not worried about the AN8 fuel line, the part im gonna upgrade is pump and add a feedline to each fuelrail insted of the stock crossover line.

#7

Wow, theres the proof for the 8AN line I guess. I just don't get it, the internal diameter of an 8AN seems like it wouldn't be too much larger than the stock 3/8ths stainless line.

I just don't get it, the internal diameter of an 8AN seems like it wouldn't be too much larger than the stock 3/8ths stainless line.

thanks for your input!

I just don't get it, the internal diameter of an 8AN seems like it wouldn't be too much larger than the stock 3/8ths stainless line.

I just don't get it, the internal diameter of an 8AN seems like it wouldn't be too much larger than the stock 3/8ths stainless line.

thanks for your input!

Last edited by SSandman; 03-17-2008 at 05:53 PM.

#9

Thanks Lisa33, sounds like good reason to use an 8AN line. Seems to be working very well for you and with maxing out an F1 im sure you are needing more fuel than i'll need with my D1SC. Im sure the smallest line I can (very) safely get away with would be best for less inertia, don't want to create more work for the pump(s). Of course having enough fuel is very crucial.

Anyone else care to share their fuel system specifics (AN size, fuel rail setup, fuel pump setup) or ignition? I know there are a lot of f/i guys here. thanks!

Anyone else care to share their fuel system specifics (AN size, fuel rail setup, fuel pump setup) or ignition? I know there are a lot of f/i guys here. thanks!

Last edited by SSandman; 03-18-2008 at 04:41 PM.

#10

You will get a lot of different opinions regarding these two issues...fuel system & ignition/Opti-spark. Several guys here have had great sucess with stock fuel lines and an upgraded fuel pump(s) as well as using the stock Opti-spark system while making 800 fwhp.

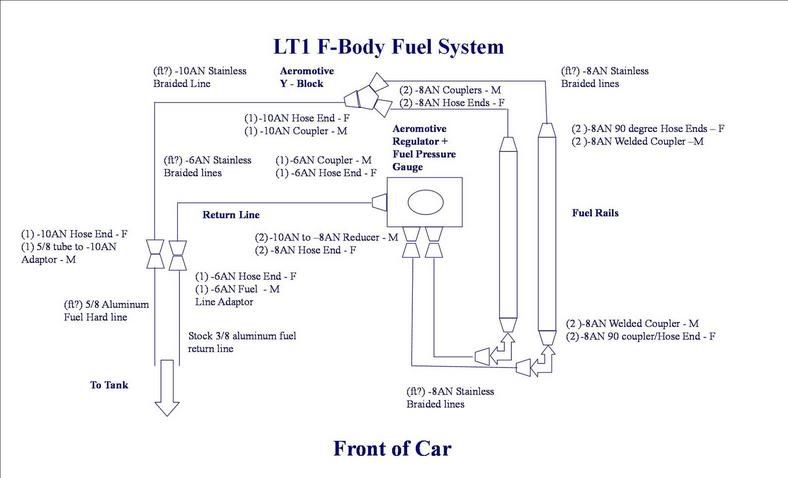

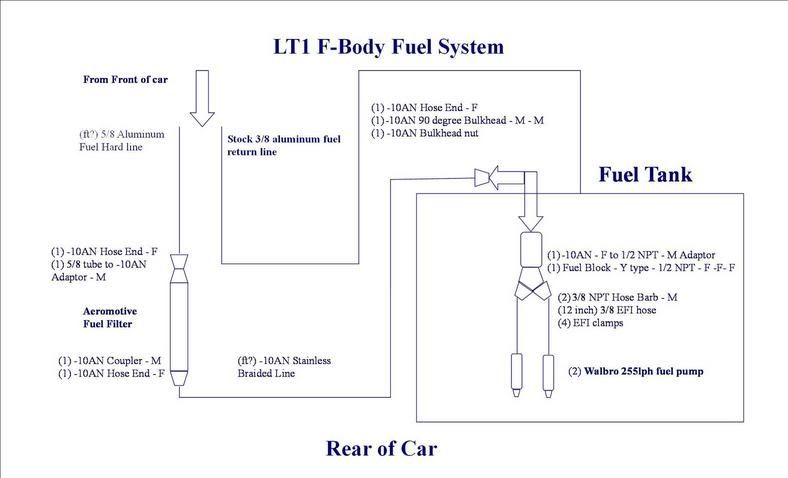

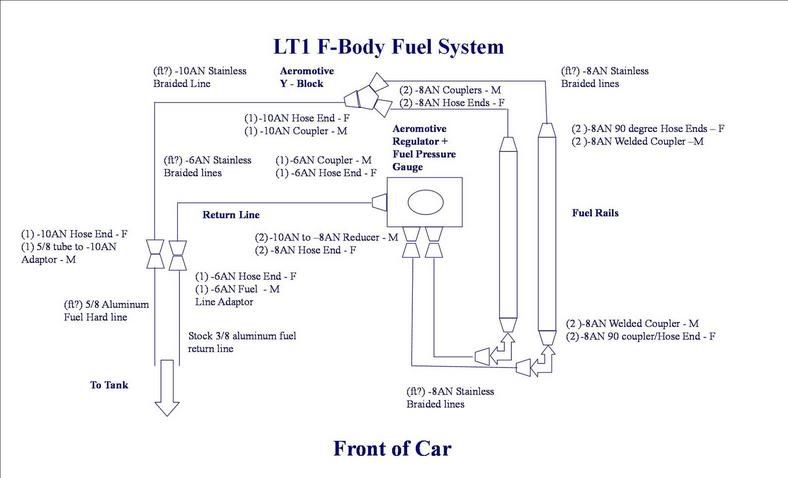

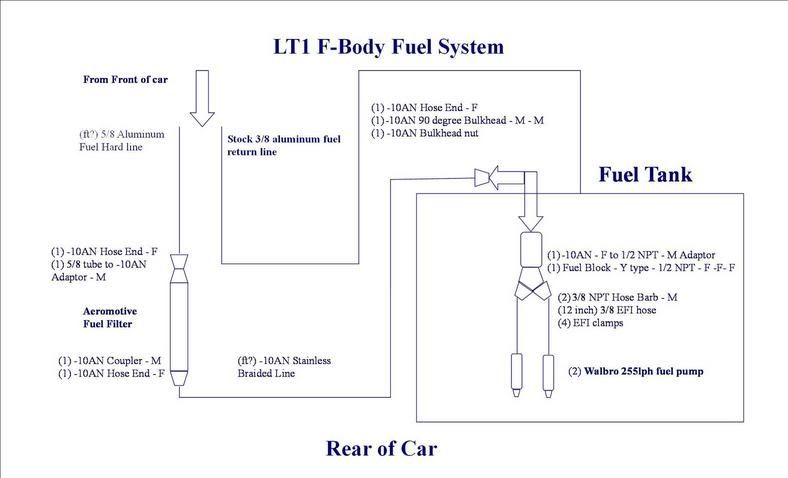

I chose to run a -8 line from the in-line Aeromotive fuel pump to a tee that then feeds the rails. The rails then return to the AFPR and I used a -6 line for the return to the tank. You may be able to get idea from the picture.

If you don't want to run a good quality Opti-spark ignition, consider using an LTCC system http://www.bailey-eng.com/ or a Delteq system, http://www.delteq.com/ both eliminate the secondary voltage inside the Opti-spark distributor which is the majority of the problem with the Opti's.

Once again, due to wanting to play it safe and the need for easy tuning, I chose to modify an LS-X Big Stuff 3 PCM system to run on the LT-1 which also allows me to run C.O.P.

I chose to run a -8 line from the in-line Aeromotive fuel pump to a tee that then feeds the rails. The rails then return to the AFPR and I used a -6 line for the return to the tank. You may be able to get idea from the picture.

If you don't want to run a good quality Opti-spark ignition, consider using an LTCC system http://www.bailey-eng.com/ or a Delteq system, http://www.delteq.com/ both eliminate the secondary voltage inside the Opti-spark distributor which is the majority of the problem with the Opti's.

Once again, due to wanting to play it safe and the need for easy tuning, I chose to modify an LS-X Big Stuff 3 PCM system to run on the LT-1 which also allows me to run C.O.P.

#11

Fuel... Been running a dual Walbro intank 255lph with a single pump#1 voltage boost with use of a Ken_Bell unit. (97ss Camaro - 383 - D1 - AFR heads with 72# Seimens injectors) What I did was fabricate my own tank transition plate to allow for two -6an socketless hose lines to a Y located @ mid car. The Y outputs to a single -8an alum/ hose line to an Aeromotive filter located in the motor compartment. I use the stock fuel return line to the tank from a boost referenced Aeromotive fuel regulator. No hobs switch, but, I can turn off pump #2 from the driver seat. Been running it for 5 years now with no problems.

Ignition... I use is a MSD 6A with a variable timing adjustment. No reduction on timing due to meth/ h20 and a large 24/10/3" Spearco IC. Also MSD 8.5mm wire and Zex power racer plugs which I lov. I've rebuilt 4 opti's and ended up with a modified stock unit. Rivet the rotor condutor, and, ditch the filter on the vent tube. I've exploded 2 opti's before I used the rivet'ed rotor.

Hope this helps. B.

Ignition... I use is a MSD 6A with a variable timing adjustment. No reduction on timing due to meth/ h20 and a large 24/10/3" Spearco IC. Also MSD 8.5mm wire and Zex power racer plugs which I lov. I've rebuilt 4 opti's and ended up with a modified stock unit. Rivet the rotor condutor, and, ditch the filter on the vent tube. I've exploded 2 opti's before I used the rivet'ed rotor.

Hope this helps. B.

#12

Thanks everyone Knowing that guys have supported as much power as i'd like to make on 8an line, what im mainly concerned about now is hoping that the 8an is enough to not burn up the 2 255lph pumps when they are both on. I mean, normally most aftermarket inline pumps have a recommended an line size so to not burn up the pump, right? Don't want to do the same with the two intank pumps due to too small of a line. I guess i'll have to talk to the pump manufacturer about that.

mzgp5x, I know what you mean about blowing up opti's. My first motor was an N/A with a big cam and I broke a rotor with that setup. I've since went to an MSD opti and while I didn't have any problems in the short time I was using it, I think i'd rather put the cap and rotor on a stock opti housing, red locktite the rotor screw and make sure the housing is sealed. I've heard of a few problems with the optical sensor part of MSD's and I have never had a problem with OEM's aside from shattering rotors.

Im a little paranoid about the aeromotive fpr that I would have to run due to feed/due return lines from my fuel rail and for using the braided line. I hear a lot of bad things about them being inconsistent , leaky, even heard of a guys car going up in flames because of one. However, I don't really know of any other brands that have a better reputation and I do see a lot of guys running them on other high hp blower setups so what is the deal? Is it an "I only run one because I have to" deal or are the problems overblown? I thought I had it all figured out till I saw a thread here reminding me of all the problems I have heard regarding aeromotive fuel pressure regulators.

mzgp5x, I know what you mean about blowing up opti's. My first motor was an N/A with a big cam and I broke a rotor with that setup. I've since went to an MSD opti and while I didn't have any problems in the short time I was using it, I think i'd rather put the cap and rotor on a stock opti housing, red locktite the rotor screw and make sure the housing is sealed. I've heard of a few problems with the optical sensor part of MSD's and I have never had a problem with OEM's aside from shattering rotors.

Im a little paranoid about the aeromotive fpr that I would have to run due to feed/due return lines from my fuel rail and for using the braided line. I hear a lot of bad things about them being inconsistent , leaky, even heard of a guys car going up in flames because of one. However, I don't really know of any other brands that have a better reputation and I do see a lot of guys running them on other high hp blower setups so what is the deal? Is it an "I only run one because I have to" deal or are the problems overblown? I thought I had it all figured out till I saw a thread here reminding me of all the problems I have heard regarding aeromotive fuel pressure regulators.

Last edited by SSandman; 03-28-2008 at 11:37 AM.

#13

Opti...

The failure in the opti is with the rotor piece that secures the brass contact. The gm opti rotor is designed with two (2) sonic welded plastic buttons that secure the brass contact.

The brass contact delivers the current to the distributor/ spark-plug wire contact. It is usually advised to run a spark enhancement device (MSD 6a or other) when application of a FI head.

I run a MSD 6a with an 8202 coil. The electrical output is greater than a stock spark (CD ignition hits 3 times per rev under 3K rpm). These sonic plastic welds can melt, thus, releasing the brass contact resulting in loose separation and massive plastic component damage.

I have drilled these plastic retainers and applied alum 1/8 rivets. I have not experience any failures since this modicfication. These rivets do not replace the rotor base screws. Please do not be confused.

I hope this helps you in your FI quest for higher adiabatic efficiency.

Fuel...

In referance to twin in tank fuel pumps, I have listed in order line size from the fuel tank.

(2) parallel operation in_tank Walbro 255 lph pumps. Seperate elect circuits.

Each pump delivers fuel to -6/ 3/8 Aeroquip socketless hose.

(2) parallel (-6an) 3/8" Soc hose exit the tank and converge in a Y located in the stock filter location. (Use of AeroQuip bulkhead fitings @ tank).

(1) -8an 1/2" Alum line exits the Y, (Y works in reverse - a Morosso part) and, is plumbed to an Aeromotive fuel cooler located directly below the drivers seat under_car attached to the pan.

(1) -8an hose exits the fuel cooler up to the motor compartment to a single Aeromotive fuel filter.

(1) -8an hose (braided) is connected to the right side fuel rail.

Fuel rails remain in series.

(1) Aeromotive fuel reg located @ end of driver side rail returns fuel to tank.

End of circuit.

B.

The failure in the opti is with the rotor piece that secures the brass contact. The gm opti rotor is designed with two (2) sonic welded plastic buttons that secure the brass contact.

The brass contact delivers the current to the distributor/ spark-plug wire contact. It is usually advised to run a spark enhancement device (MSD 6a or other) when application of a FI head.

I run a MSD 6a with an 8202 coil. The electrical output is greater than a stock spark (CD ignition hits 3 times per rev under 3K rpm). These sonic plastic welds can melt, thus, releasing the brass contact resulting in loose separation and massive plastic component damage.

I have drilled these plastic retainers and applied alum 1/8 rivets. I have not experience any failures since this modicfication. These rivets do not replace the rotor base screws. Please do not be confused.

I hope this helps you in your FI quest for higher adiabatic efficiency.

Fuel...

In referance to twin in tank fuel pumps, I have listed in order line size from the fuel tank.

(2) parallel operation in_tank Walbro 255 lph pumps. Seperate elect circuits.

Each pump delivers fuel to -6/ 3/8 Aeroquip socketless hose.

(2) parallel (-6an) 3/8" Soc hose exit the tank and converge in a Y located in the stock filter location. (Use of AeroQuip bulkhead fitings @ tank).

(1) -8an 1/2" Alum line exits the Y, (Y works in reverse - a Morosso part) and, is plumbed to an Aeromotive fuel cooler located directly below the drivers seat under_car attached to the pan.

(1) -8an hose exits the fuel cooler up to the motor compartment to a single Aeromotive fuel filter.

(1) -8an hose (braided) is connected to the right side fuel rail.

Fuel rails remain in series.

(1) Aeromotive fuel reg located @ end of driver side rail returns fuel to tank.

End of circuit.

B.

#14

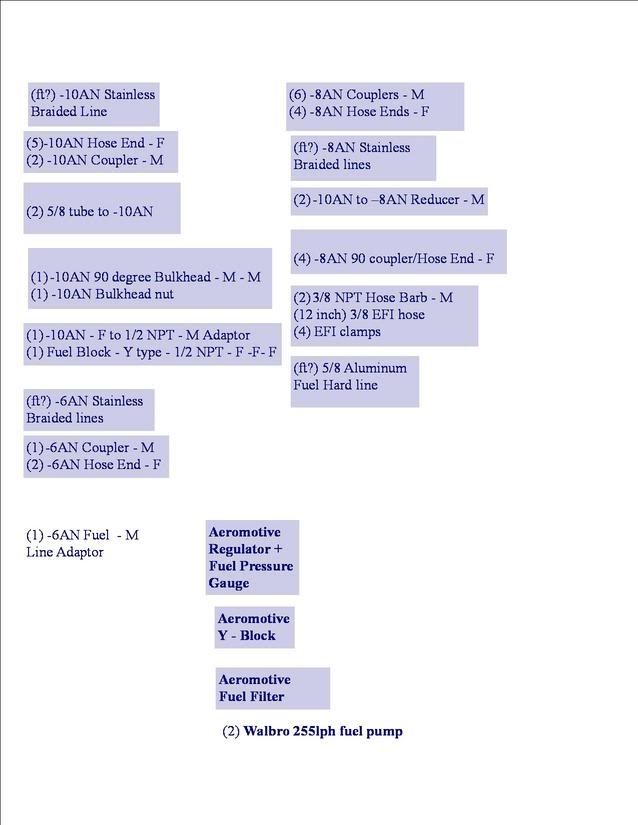

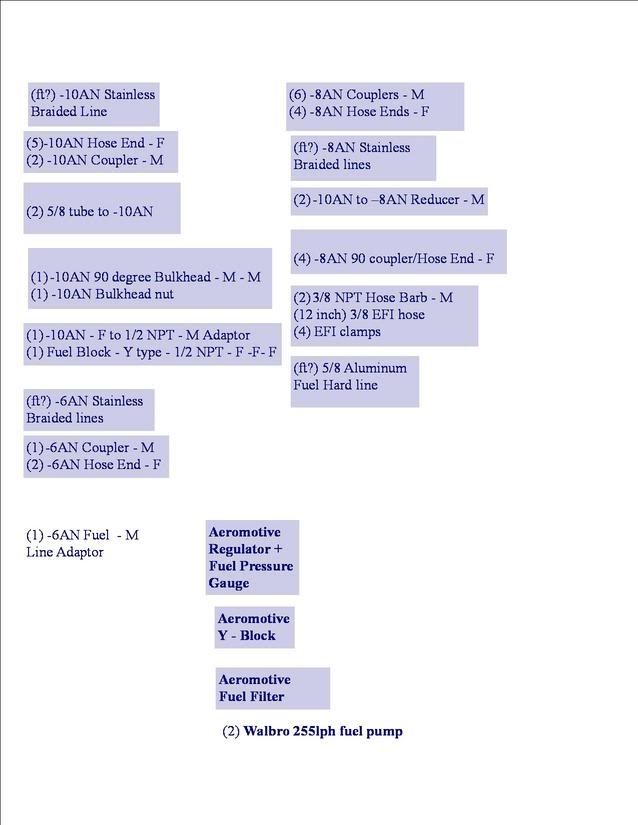

-12AN is WAAAY OVERKILL. All that you would ever need is -10AN unless you plan on making over 1500HP. I came up with a diagram a while back to build a fuel system using intank pumps. Here you go:

I incorporated hard fuel lines because its WAAAAAAY cheaper than braided stainless. There is no need to do bradied stainless from tank to the rails.

-B

I incorporated hard fuel lines because its WAAAAAAY cheaper than braided stainless. There is no need to do bradied stainless from tank to the rails.

-B

#15

I'm a Turbo guy so don't take this the wrong way but why don't you keep that 100hp your throwing away?

Do a turbo setup!!!! You'd have less in it than buying a 5000.00 (supercharger...

Ok.. done with that if you've got your heart set on a supercharger.

-12 is way too big.

I run -10AN (Nylon/stainless) like nitrous line. for feed and -6 for return.

-10 from tank to Aeromotive pump then -8 to fuel rail.(clarify) As others have said that'll support more than enough for the needs your asking about.

No clue about LT1 Ignitions.. Experts here can help with that.

Your power levles are very acheivable with the parts you described. Don't worry about the 4000lbs... We run good numbers with the 4000lb Typhoons with only 6cyl and running 2 more wheels

If your interested in custom turbo setup It's possible.

~Scott

Buick V6 in my 86 Camaro

.JPG)

__________________

Do a turbo setup!!!! You'd have less in it than buying a 5000.00 (supercharger...

Ok.. done with that if you've got your heart set on a supercharger.

-12 is way too big.

I run -10AN (Nylon/stainless) like nitrous line. for feed and -6 for return.

-10 from tank to Aeromotive pump then -8 to fuel rail.(clarify) As others have said that'll support more than enough for the needs your asking about.

No clue about LT1 Ignitions.. Experts here can help with that.

Your power levles are very acheivable with the parts you described. Don't worry about the 4000lbs... We run good numbers with the 4000lb Typhoons with only 6cyl and running 2 more wheels

If your interested in custom turbo setup It's possible.

~Scott

Buick V6 in my 86 Camaro

__________________