383 build

#31

Re: 383 build

How does that piston dish affect your static compression ratio calculations? Wiseco also adds compression height to some of their pistons to reduce effective deck height.

Is the gross lift on the cam w/ 1.5X or 1.6X rockers? And the heads are stock, except for a "valve job"?

And just to help you make your posts accurate.... the stock gears with the T56 are 3.42:1, not 3:43.

Is the gross lift on the cam w/ 1.5X or 1.6X rockers? And the heads are stock, except for a "valve job"?

And just to help you make your posts accurate.... the stock gears with the T56 are 3.42:1, not 3:43.

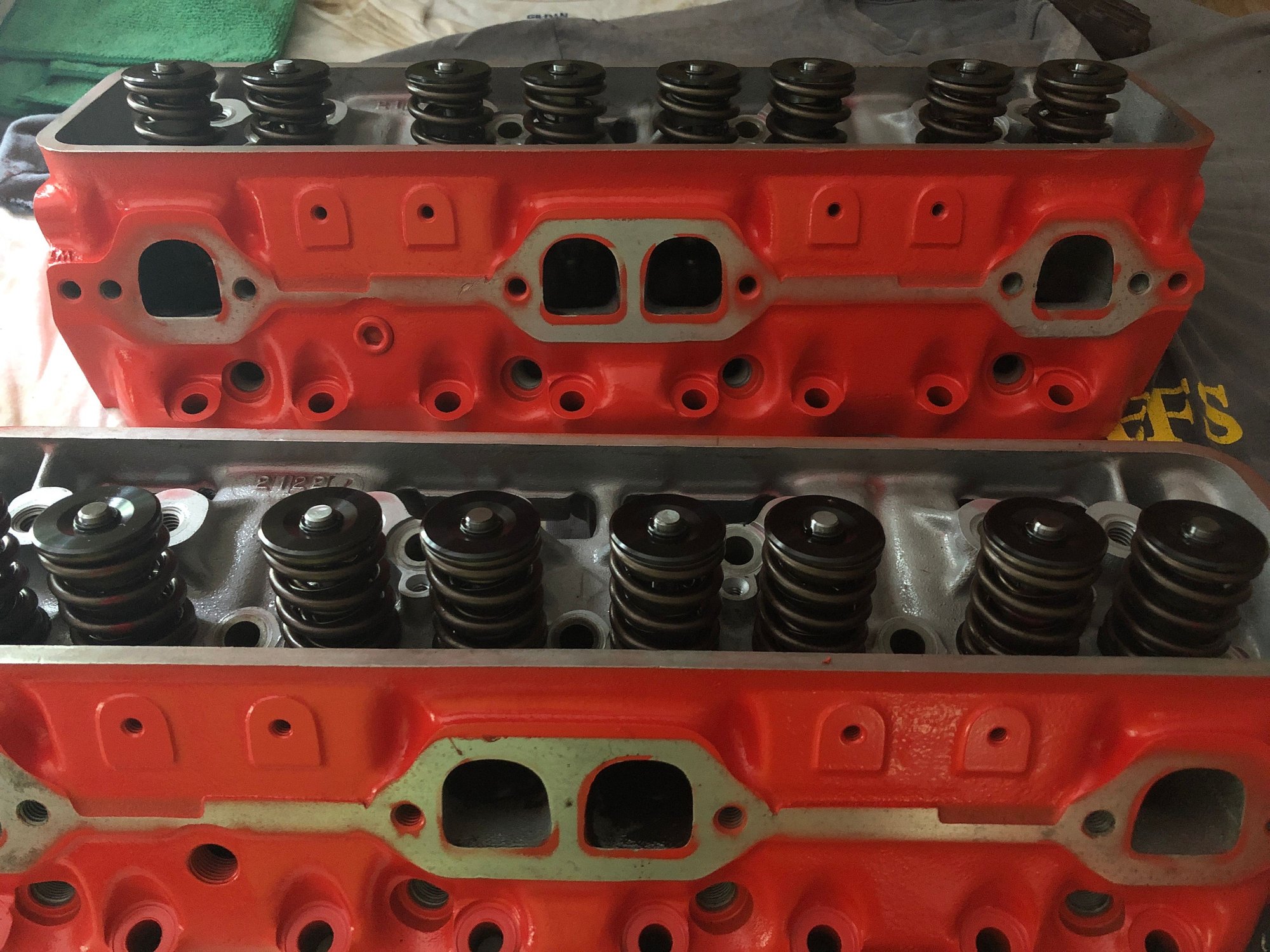

lt1 heads 3 way valve job. Bowl blended.

correct. 3:42

1.5

I do know he decked it for the stock heads because he called me before he decked it To make sure

#32

#33

#34

Re: 383 build

But what dish volume did you put in the calculator? That dish is way larger than the usual volume of the typical flat top with two partial valve reliefs.

Look carefully..... NOT 3:42.....the correct notation is 3.42. No "colon", just a "period". May seem unimportant, but it pays to be correct. The driveshaft rotates 3.42 times to make the wheels go around once.

Then you will replace these with 1.6's when you upgrade the heads?

So, what deck height did you measure and use in the CR calculation? Were the heads milled at all? Did the shop measure the combustion chambers?

correct. 3:42

1.5

I do know he decked it for the stock heads because he called me before he decked it To make sure

#35

Re: 383 build

Thank you. I am learning and do appreciate and understand the need to be accurate.

I would use 1.6 rockers when and if I go back into the motor. Most likely I wonít for a while. Iím sure the car will do all I need it to. Iím not sure on the calculations. I donít have all the specs but Iíll have a build sheet when Iím done. My guy has been building race engines for 30 years and is doing all the calculations and precision work. Iím simply putting it together slowly with his direction. He wanted me to do the assembly. A feather in the hat when I open the hood .

I would use 1.6 rockers when and if I go back into the motor. Most likely I wonít for a while. Iím sure the car will do all I need it to. Iím not sure on the calculations. I donít have all the specs but Iíll have a build sheet when Iím done. My guy has been building race engines for 30 years and is doing all the calculations and precision work. Iím simply putting it together slowly with his direction. He wanted me to do the assembly. A feather in the hat when I open the hood .

#36

Re: 383 build

I have a question regarding ac and EGR delete on my current 383 build.

I donít plan on running ac until maybe next year. Also Iím hopeful that deleting the egr system will eliminate the vacuum pump etc.

Iíve not done any research yet.

any advice on eliminating the two.

ac compressor and smog/ vacuum pump and egr delete.

What is the best solution for the O2 sensors?

we donít have emissions in my county. I plan to use Hedman long tube headers.

also Iíll be using 1.6 scorpion roller rockers not the 1.5 as mentioned previously

i will be using the lunati cam above.

any advice would be great. God bless.

I donít plan on running ac until maybe next year. Also Iím hopeful that deleting the egr system will eliminate the vacuum pump etc.

Iíve not done any research yet.

any advice on eliminating the two.

ac compressor and smog/ vacuum pump and egr delete.

What is the best solution for the O2 sensors?

we donít have emissions in my county. I plan to use Hedman long tube headers.

also Iíll be using 1.6 scorpion roller rockers not the 1.5 as mentioned previously

i will be using the lunati cam above.

any advice would be great. God bless.

#37

Re: 383 build

EGR system has nothing to do with the AIR (not "vacuum") pump, except on the 1993 models.

The AIR pump supplies air to the exhaust manifolds for 3 minutes or so at startup. The injected air helps burn the unburned gasoline that results from the very rich A/F mixture that is required on cold start. In addition, the burning of the hydrocarbons in the exhaust helps the cat(s) and O2 sensors heat up faster and start to work. After a few minutes the AIR pump shuts off and is not used again. It has no effect on engine HP. If you delete the cat(s), you really don't need the AIR system. But the PCM need to have the AIR "programmed out" (96/97) or it will set codes. Again, this system has no relation to EGR in the 94-97 cars.

The EGR system is useful in that is helps prevent engine knock (detonation) when you lug the engine at low RPM. As long as the EGR system is working the way it is supposed to, it has no impact on HP. It is not used at idle, not used at WOT, and not used above 3,600 RPM. Deleting it is simple - block off the EGR connection on the headers (it the headers even have them), block off the mounting location for the EGR valve, block the connection on the back of the intake manifold for the corrugated riser tube (strictly cosmetic, but just do it). Cap the source of vacuum for the EGR solenoid. Have the EGR "programmed out" of the PCM to avoid codes.

Which O2 sensors are you asking about? The pre-cat O2 sensors are required for the PCM to control fuel to the engine. Do not delete. The after-cat O2 sensors are only required if you are running cats. If no cats, no after-cat O2 sensors needed, but again they need to to be "programmed out" of the PCM or you will get codes (96/97)

Deleting A/C is purely a personal preference. You need an "A/C delete" pulley and bracket that gets installed in place of the A/C compressor pulley, and possibly a different length belt.

The AIR pump supplies air to the exhaust manifolds for 3 minutes or so at startup. The injected air helps burn the unburned gasoline that results from the very rich A/F mixture that is required on cold start. In addition, the burning of the hydrocarbons in the exhaust helps the cat(s) and O2 sensors heat up faster and start to work. After a few minutes the AIR pump shuts off and is not used again. It has no effect on engine HP. If you delete the cat(s), you really don't need the AIR system. But the PCM need to have the AIR "programmed out" (96/97) or it will set codes. Again, this system has no relation to EGR in the 94-97 cars.

The EGR system is useful in that is helps prevent engine knock (detonation) when you lug the engine at low RPM. As long as the EGR system is working the way it is supposed to, it has no impact on HP. It is not used at idle, not used at WOT, and not used above 3,600 RPM. Deleting it is simple - block off the EGR connection on the headers (it the headers even have them), block off the mounting location for the EGR valve, block the connection on the back of the intake manifold for the corrugated riser tube (strictly cosmetic, but just do it). Cap the source of vacuum for the EGR solenoid. Have the EGR "programmed out" of the PCM to avoid codes.

Which O2 sensors are you asking about? The pre-cat O2 sensors are required for the PCM to control fuel to the engine. Do not delete. The after-cat O2 sensors are only required if you are running cats. If no cats, no after-cat O2 sensors needed, but again they need to to be "programmed out" of the PCM or you will get codes (96/97)

Deleting A/C is purely a personal preference. You need an "A/C delete" pulley and bracket that gets installed in place of the A/C compressor pulley, and possibly a different length belt.

#39

Re: 383 build

what do you recommend for oil pan and pump?

I would like to upgrade but not spend a ridiculous amount of money.

my guy tells me to stay with a stock volume pump( new) but a better pan ( more volume)

I would like to upgrade but not spend a ridiculous amount of money.

my guy tells me to stay with a stock volume pump( new) but a better pan ( more volume)

#40

Re: 383 build

Stock oil pan is fine. Stock oil pump is fine, but if you can find a shop that knows how to blueprint the pump, it makes it even better. Stock pressure relief spring is 60 PSI. Replace it with the 80 PSI “white spring”. Depending on your specific 3.75” stroke crankshaft, the stock pan may require a few carefully placed taps with a light hammer for clearance.

The oil pump drive shaft is effectively in two pieces. The upper “stub” hold the drive gear. This is required because of the lack of a conventional distributor for the cam to drive. The “stub” is retained/located in the lifter valley by a plastic cap that is part of the stub, and bolts to the block. For anything other than a stock rebuild, this oil pump drive “stub” should be replaced with one that has a metal retainer/locator cap.

Be sure to retain the stock windage tray.

My 800 HP/800 lb-ft, 7,400 RPM redline stroker is set up as above. A friend reliably made 1,125 HP at the flywheel with the same setup. Same shop assembled both engines. He was glad he had the stock pan, because he had to replace it twice after droppng the car hard after 3-foot wheelstands..

The oil pump drive shaft is effectively in two pieces. The upper “stub” hold the drive gear. This is required because of the lack of a conventional distributor for the cam to drive. The “stub” is retained/located in the lifter valley by a plastic cap that is part of the stub, and bolts to the block. For anything other than a stock rebuild, this oil pump drive “stub” should be replaced with one that has a metal retainer/locator cap.

Be sure to retain the stock windage tray.

My 800 HP/800 lb-ft, 7,400 RPM redline stroker is set up as above. A friend reliably made 1,125 HP at the flywheel with the same setup. Same shop assembled both engines. He was glad he had the stock pan, because he had to replace it twice after droppng the car hard after 3-foot wheelstands..

Last edited by Injuneer; 09-26-2020 at 12:38 AM.

#41

Re: 383 build

#43

Re: 383 build

Any good SBC engine builder should know how to do it. There used to be “how to” guides on the ‘net, but I haven’t been able to find one in recent years. I don't know the details.

There are sources that claim to make them. Example:

https://www.cpperformance.com/p-1234...-oil-pump.aspx

There are sources that claim to make them. Example:

https://www.cpperformance.com/p-1234...-oil-pump.aspx

#44

Re: 383 build

After researching the info given on the blueprinting and examining my pump I can see the importance of it. Precious oil pumps sells them if I canít get mine done reasonably. Are you familiar with these pumps?

seems reasonable for $120

im thinking of getting the trick flow 30 lb injectors.

Based on the equation in the book Iíve purchased from your recommendation earlier.

I need 29.8... lbs.

can I run my stock fuel pump for a couple hundred miles or so until I can replace it.

what pump was it you recommended?

seems reasonable for $120

im thinking of getting the trick flow 30 lb injectors.

Based on the equation in the book Iíve purchased from your recommendation earlier.

I need 29.8... lbs.

can I run my stock fuel pump for a couple hundred miles or so until I can replace it.

what pump was it you recommended?

#45

Re: 383 build

Question. Itís time to start my car. Unfortunately itís not turning over. I lost the keys and GM dealer gave me a key that is supposed to be the correct vats key resistance. I can hear the fuel system priming but starter does not engage. The security light is flashing when attempting to start. I believe everything is plugged in as far as the wire harness goes. Is there something I might be missing or advise