AI200cc stock bottom end dyno results, 429rwhp with a miss

#136

You are also ignoring the fact that I went from a ported intake manifold to a stock one. Doing your ricer math that's worth atleast 15rwhp on a high hp car, so that means I gained over 40rwhp with my new heads.

#137

I can tell you guys my results and take them as you will, Lloyd ported my first set of heads for me back in 2003 or so and I have only gone faster since with his portwork, which picked my car from 12.00@113mph (stock heads) to 11.61@117mph, same heads, same valves, same cam (LE1), same everything. I removed the heads sent them to Lloyd then reinstalled the heads and ran .4 tenths faster and 4mph on the first nite out. I then sprayed 150HP n2o and broke some main bearing caps (detonation) so I never got to really dial in that setup that would have easily run 11.40's with some tweaking. vbut i went with some LE2's and bigger cam 11.20@120mph and on n2o 10.20@132mph So his porting definately makes HP and stuff breaks in the high performance world no matter who you are. Later Clint

#138

Comparing my car to Ricks is not comparing apples to apples. My car still has a factory PCM, runs on pumpgas, drag radials and cruises down the road when the weather is nice not like his racecar that is a 383, high compression, aftermarket PCM full race suspension etc.... My goal is to run 10's N/A and on my very first outing the car ran 11.00@121mph with a very bad miss at anything over 6,300rpms on 1-2 shift and 2-3 shift so the car has alot left in it. I don't want to run 10.99 either but it should run 10.60-70's@125+mph once I get the miss out and get all the little things addressed. I bought an LTCC with the coils to try and fix the upper rpm miss and I should make some passes this month. I don't think anyone can argue with a legit streetcar that runs 10's on motor (355")with full exhaust, drag radials, pumpgas, weighs over 3,400lbs and will run deep 9's on spray so you wanna race with your AI heads?

#139

Just out of curiosity Lloyd, what is your excuse that the vavlespring installed height varied from 1.75-1.80" on your LE2 heads when I checked it? Shouldn't it all be installed at the same height, expecially since the cam I was running had the most aggressive hydrolic roller lobes comp sells? Even more aggressive than the LSK LSx lobes that bret bashes and the XFI lobes that he also bashes since they are so "aggressive"? My 224 cam had more duration at .200" lift than the cc306 by almost 10 degrees.

I guess I was lucky that I pulled the motor apart before the lobe started coming apart. The valvefloat only took out the rollers on a few of my lifters... I've also gotten numerous PM's from members on this board since they are having similar problems.

I guess I was lucky that I pulled the motor apart before the lobe started coming apart. The valvefloat only took out the rollers on a few of my lifters... I've also gotten numerous PM's from members on this board since they are having similar problems.

#140

Yeah that's what he should have done but he didn't. It's his job to set up the spring height when he is selling assembled heads.

#141

tireburnin, do you read the stuff you type? Do you know how a cnc machine works? Have you ever heard of altering some of the ports that would be lacking in the first place? And granted, not that this would apply in all cases.

A cnc head is nothing more than a copy. Oh wait, I'm off by

1 cc, let me go back and fix that.

A cnc head is nothing more than a copy. Oh wait, I'm off by

1 cc, let me go back and fix that.

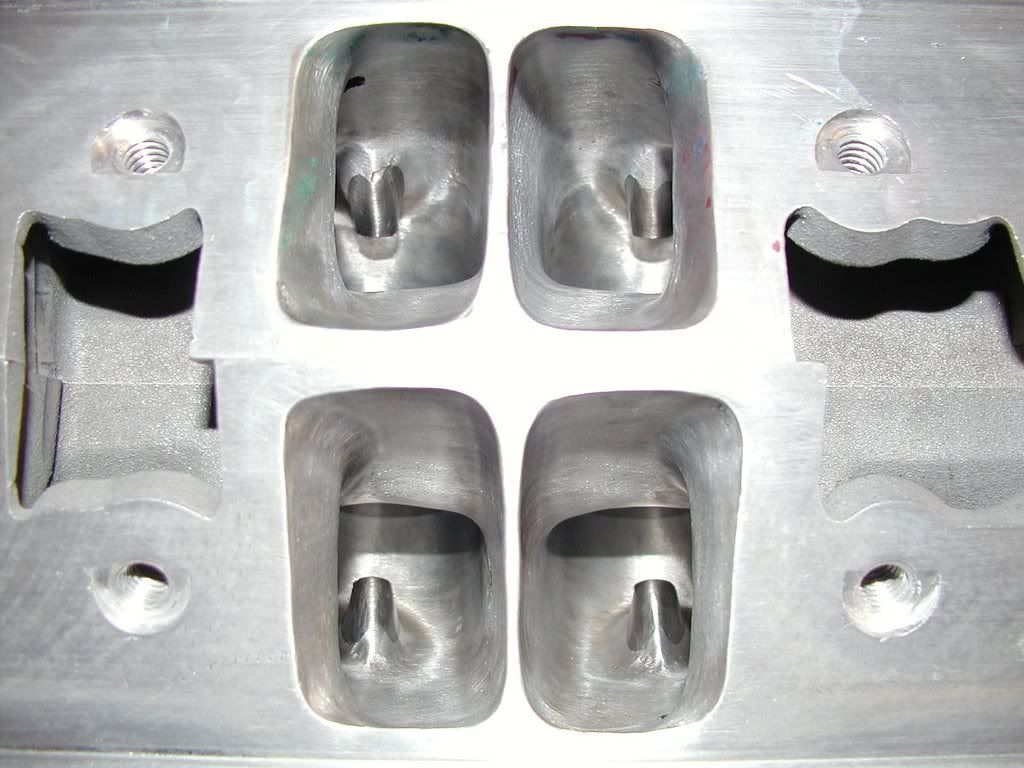

Porter "A" uses a CNC machine, porter "B" does it by hand. Both recieve the same head and for the first example, it is an un ported head. Company A checks to make sure the head is good (shift etc) and throws it on the CNC machine. All ports come out to 200cnc, looking sharp and an identical copy of the original programmed head. Company B gets the same head and checks it for shift etc. Company B goes to town on it by hand. Some ports end up 205, some end up 208 etc. Every port is different than the last with the only control variables being in the porters hand.

Now both companies recieve a mildly ported head. In this example it will be Speed Demons. Both A and B look over the head and company A says "This won't fit my program as too much material has been removed" or "There was little work done to this head and plenty of metal to get our port in there." Instance 1 company A sends it back, instance 2 there was plenty of material for the bigger port and the head comes out damn close to 200cc and very close to the original CNC design because they made the choice that enough material would be left to put out a good product.

Now company B gets Speed Demons head and looks over it. B comes to the decision that there is plenty of room to work with this head and a good port can still be made with the preexisting work taken into account. Company B goes to town on the head like a child carving a pumpkin and the head ends up 218cc?

How does this happen? A head porter looks at a head with existing porting and decides they have enough material to work with. If the head was so mangled and so much material missing, why port it? Why show 30cfm gains? Why put it out the door knowing consistency was that far off?

#142

See, now youv'e gone and done it again. The springs don't have the same pressure from spring to spring, plus the fact that the heads are not perfect from one spring seat to another. Therefore you shim the springs to different heights to get the closed and open pressure as close as possible.

#143

Comparing my car to Ricks is not comparing apples to apples. My car still has a factory PCM, runs on pumpgas, drag radials and cruises down the road when the weather is nice not like his racecar that is a 383, high compression, aftermarket PCM full race suspension etc.... My goal is to run 10's N/A and on my very first outing the car ran 11.00@121mph with a very bad miss at anything over 6,300rpms on 1-2 shift and 2-3 shift so the car has alot left in it. I don't want to run 10.99 either but it should run 10.60-70's@125+mph once I get the miss out and get all the little things addressed. I bought an LTCC with the coils to try and fix the upper rpm miss and I should make some passes this month. I don't think anyone can argue with a legit streetcar that runs 10's on motor (355")with full exhaust, drag radials, pumpgas, weighs over 3,400lbs and will run deep 9's on spray so you wanna race with your AI heads?

And I guess a 3470lb car with a 4l60e is a gutted race car. And you're telling me you are running completly stock suspension components? It has to have a 10 pt cage and all the other saftey equipment because of the e.t. and MPH he runs, but I'm sure you knew that.

And I guess a 3470lb car with a 4l60e is a gutted race car. And you're telling me you are running completly stock suspension components? It has to have a 10 pt cage and all the other saftey equipment because of the e.t. and MPH he runs, but I'm sure you knew that.

#144

See, now youv'e gone and done it again. The springs don't have the same pressure from spring to spring, plus the fact that the heads are not perfect from one spring seat to another. Therefore you shim the springs to different heights to get the closed and open pressure as close as possible.

#145

Throwing his posting history out there during the time of the problem doesn't show anything. (Tireburnin)

as I mentioned, most people found my post enlightening and then as I stated, there are opthrs that had their mind made up when lgging on.

I told Speed Demon the heads were gasket matched and would never be "just like" they would be if I started with an untouched set but I could help them a great deal over what they were. He was happy with that.

2 areas that had more material removed were at the gasket area and on exhaust wall side of intake bowl next to guide as mentioned.

If you were to run a CNC program and the heads were larger than the program in these areas, they would remain untouched and effect runner volume from what it would ahve been if starting with an otherwise stock head. That is as plain as I can put it. Only advantage hand portwork has in this instance is to blend these areas in better.

lloyd

as I mentioned, most people found my post enlightening and then as I stated, there are opthrs that had their mind made up when lgging on.

I told Speed Demon the heads were gasket matched and would never be "just like" they would be if I started with an untouched set but I could help them a great deal over what they were. He was happy with that.

2 areas that had more material removed were at the gasket area and on exhaust wall side of intake bowl next to guide as mentioned.

If you were to run a CNC program and the heads were larger than the program in these areas, they would remain untouched and effect runner volume from what it would ahve been if starting with an otherwise stock head. That is as plain as I can put it. Only advantage hand portwork has in this instance is to blend these areas in better.

lloyd

#147

Throwing his posting history out there during the time of the problem doesn't show anything. (Tireburnin)

as I mentioned, most people found my post enlightening and then as I stated, there are opthrs that had their mind made up when lgging on.

I told Speed Demon the heads were gasket matched and would never be "just like" they would be if I started with an untouched set but I could help them a great deal over what they were. He was happy with that.

2 areas that had more material removed were at the gasket area and on exhaust wall side of intake bowl next to guide as mentioned.

If you were to run a CNC program and the heads were larger than the program in these areas, they would remain untouched and effect runner volume from what it would ahve been if starting with an otherwise stock head. That is as plain as I can put it. Only advantage hand portwork has in this instance is to blend these areas in better.

lloyd

as I mentioned, most people found my post enlightening and then as I stated, there are opthrs that had their mind made up when lgging on.

I told Speed Demon the heads were gasket matched and would never be "just like" they would be if I started with an untouched set but I could help them a great deal over what they were. He was happy with that.

2 areas that had more material removed were at the gasket area and on exhaust wall side of intake bowl next to guide as mentioned.

If you were to run a CNC program and the heads were larger than the program in these areas, they would remain untouched and effect runner volume from what it would ahve been if starting with an otherwise stock head. That is as plain as I can put it. Only advantage hand portwork has in this instance is to blend these areas in better.

lloyd

When I asked "So does this mean that the ports are still in ok shape for porting and there is nothing that was done that can't be fixed on the ports?

You said

"The port job is not bad and is not a "hack job". It was a nice port job (concentric and ports matched each other) but not much done."

"Most places would consider this a stage I port job and with a lil more work and larger valve, they would be on par with what GTP considers a stage II. Nothing wrong with what was done, just not much done. "

#148

Between the two of you, never mind, lets just say this could go on for days and you still won't get it.

Short and sweet, one thinks he has the hot set up, while blowing blue smoke out the exhaust. Never mind he has a M6 and a 10 bolt, to help his #s and who knows how forgiving the dyno was that day.

The other guy has an AI top end and because of that, it's the only way to go. Please impress me with some track times. I have no favorite. LE, AI, it's all good. But the two in question here, lets see some track #s. See ya

Short and sweet, one thinks he has the hot set up, while blowing blue smoke out the exhaust. Never mind he has a M6 and a 10 bolt, to help his #s and who knows how forgiving the dyno was that day.

The other guy has an AI top end and because of that, it's the only way to go. Please impress me with some track times. I have no favorite. LE, AI, it's all good. But the two in question here, lets see some track #s. See ya

#149

Trick flow and GM guide plates are the correct ones to buy and supposed to work with LT1 heads. That doesn't mean the rockers will all line up correctly due to the way LT1 guides are machined/installed at GM. Just look at you rocker in that pic.

Most people use them and have no problems. It is not a variance in the guideplates from set to set. It is a variance in the LT1 heads and guides from set to set.

If the GM/Trick flow guide plates do not align ALL of the rockers correctly, the only way to get things exact is with the Isky adjustables and go through the hell of doing it.

Some cars will always be faster than others with the same work done. Your car was hauling *** with the GM 846, BRE cam, etc, and always ren better than most with the same mods. Starting with a "good" bottom end with only .020 deck ht can be part of it as opposed to some at .025-.035 and somke can be your exhaust, etc but for what ever reason, some cars are always fast (even in stock form) compared to others with the same gear/mods.

Firt you mentioned the LE heads were worth 4 tenths and 4 MPH when installed but now you say they gained you nothing or slowed you down.

First you said you did not check PR length on the LE heads and just used what you had and then you said you did check PR length (although that will not fix the rocker sitting on the valve wrong from side to side).

Did you ever compare the guide plates that were worn and see if those guides were toast also.

Regardless, it matters very little now anyway, you sem happy with the results of your new set up and learned alot about rocker/PR geometry as shown on your pohoto bucket.

I just found the post and wnated to post some info from the other point of view. As you know, there are 3 sides to every story regardless of how unbiased both of us feel we are when telling it. I am a very level headed person that wanted my side heard to balance the post out.

I really feel that you believe you did not damage the guides however right/wrong you are.

I really believe that you destroyed the guides and I did pay shipping both ways ($120) to look them over and have my machinist look them over to come to the same conclusion. I saw the same thing I was expecting before you shipped them but wanted to give you the benefit of the doubt and it see if there was anything done that would cause this.

Lloyd

Most people use them and have no problems. It is not a variance in the guideplates from set to set. It is a variance in the LT1 heads and guides from set to set.

If the GM/Trick flow guide plates do not align ALL of the rockers correctly, the only way to get things exact is with the Isky adjustables and go through the hell of doing it.

Some cars will always be faster than others with the same work done. Your car was hauling *** with the GM 846, BRE cam, etc, and always ren better than most with the same mods. Starting with a "good" bottom end with only .020 deck ht can be part of it as opposed to some at .025-.035 and somke can be your exhaust, etc but for what ever reason, some cars are always fast (even in stock form) compared to others with the same gear/mods.

Firt you mentioned the LE heads were worth 4 tenths and 4 MPH when installed but now you say they gained you nothing or slowed you down.

First you said you did not check PR length on the LE heads and just used what you had and then you said you did check PR length (although that will not fix the rocker sitting on the valve wrong from side to side).

Did you ever compare the guide plates that were worn and see if those guides were toast also.

Regardless, it matters very little now anyway, you sem happy with the results of your new set up and learned alot about rocker/PR geometry as shown on your pohoto bucket.

I just found the post and wnated to post some info from the other point of view. As you know, there are 3 sides to every story regardless of how unbiased both of us feel we are when telling it. I am a very level headed person that wanted my side heard to balance the post out.

I really feel that you believe you did not damage the guides however right/wrong you are.

I really believe that you destroyed the guides and I did pay shipping both ways ($120) to look them over and have my machinist look them over to come to the same conclusion. I saw the same thing I was expecting before you shipped them but wanted to give you the benefit of the doubt and it see if there was anything done that would cause this.

Lloyd

#150

Are you referring to Tireburnin's track numbers? They've been posted. Or are you referring to updated track times for Seed Demon's? As a bonus, you have both Speed Demon's dyno numbers to compare, or did we determine the Canton gave him an unfair advantage?