I'm having 2nd thoughts on installing my LT4 ED Timing Set...

#16

but it also works against your engine... it is just a known fact that you gain horsepower and valve timing improvements from removing the cam driven gear and setup, plugging it up and installing an electric motor that is easily accessable and runs from the battery with a simple relay in between. This guy made a picture walkthrough.. I bought my pump already, waiting to get advice on the best heavy duty timing set to get so I can do that while I am removing the gear for the dang waterpump that suuuux. it also goes from high horsepower engines that are stressing the belt system. Preloads the bearing down and you get the leak... onto the opti.... I can think of more reasons to replace it with an electric.... Why dont we have manual engine fans any more?? Because electric ones are MUCH better!

http://ken.lowrance.com/projects/CSI...mp/Default.htm

this guy is awesome.. Even gives you the part numbers... how easy can it be?!

http://ken.lowrance.com/projects/CSI...mp/Default.htm

this guy is awesome.. Even gives you the part numbers... how easy can it be?!

#17

but it also works against your engine... it is just a known fact that you gain horsepower and valve timing improvements from removing the cam driven gear and setup, plugging it up and installing an electric motor that is easily accessable and runs from the battery with a simple relay in between. This guy made a picture walkthrough.. I bought my pump already, waiting to get advice on the best heavy duty timing set to get so I can do that while I am removing the gear for the dang waterpump that suuuux. it also goes from high horsepower engines that are stressing the belt system. Preloads the bearing down and you get the leak... onto the opti.... I can think of more reasons to replace it with an electric.... Why dont we have manual engine fans any more?? Because electric ones are MUCH better!

http://ken.lowrance.com/projects/CSI...mp/Default.htm

this guy is awesome.. Even gives you the part numbers... how easy can it be?!

http://ken.lowrance.com/projects/CSI...mp/Default.htm

this guy is awesome.. Even gives you the part numbers... how easy can it be?!

But the number one reason for not going EWP for me is the fact that when it goes you are left stranded...and it will quit working one day. For a daily driver that is something I don't want to risk, and the fact my wife drives it and either she would be left on the side of the road scared out of her mind that some lunatic is going to stop, or she would never notice the temp gauge and keep drving till the motor seized.

If the timing set is installed correctly, and the wp bearing are not super tight, and your oil galley holes are not plugged, you should get 75k+ miles out of your gear drive pump...and when it goes, it still at least pumps water but has a little leak. If you look at the opti, its sealed up pretty well, it will take a gushing of water to ruin it, especially a vented opti...a little drip from the pump isn't going to kill it everytime...and replacing an opti is much easier to deal with than the 2 scenarios mentioned above when the EWP bites the dust.

#18

The fact that the waer pump is electric powered does not magically eliminate the load on the engine. It draws the power to drive the pump from the alternator, and the alternator has to consume more power to make more power. And of course the alternator is not 100% efficient in creating electric power from mechanical power. To attribute all this to some sort of magic improvement in electric motor efficiency is naive, at best.

Electric water pumps show a saving in HP at high engine RPM because they are pumping less water. Whether your engine needs the extra flow produced by the mechanical pump is what should determine whether you want the limitation in max flow imposed by the electric pump. The shop that built my engine wouldn't even consider putting an electric pump on an engine with a 300-shot of nitrous, and the potential for damage without adequate head cooling at 7,000 RPM. My ED LT4 set has been hapilly driving the water pump for 7 years now, and its also driving a solid roller cam with some hefty spring pressures. No water leaks, no "bearing preload" problems.........

Electric fans are used because they can be turned on and off. Why consume power when the fan isn't needed. Yes, an electric fan is "better" for that application, but only because of the "on/off" feature. The electric water pump does not offer the same advantage, since its not really an "on/off" application.

Electric water pumps show a saving in HP at high engine RPM because they are pumping less water. Whether your engine needs the extra flow produced by the mechanical pump is what should determine whether you want the limitation in max flow imposed by the electric pump. The shop that built my engine wouldn't even consider putting an electric pump on an engine with a 300-shot of nitrous, and the potential for damage without adequate head cooling at 7,000 RPM. My ED LT4 set has been hapilly driving the water pump for 7 years now, and its also driving a solid roller cam with some hefty spring pressures. No water leaks, no "bearing preload" problems.........

Electric fans are used because they can be turned on and off. Why consume power when the fan isn't needed. Yes, an electric fan is "better" for that application, but only because of the "on/off" feature. The electric water pump does not offer the same advantage, since its not really an "on/off" application.

#19

Your alternator will work harder internally to put out the same voltage when a load is placed on it. It doesn't make your engine work harder. It supplies as much voltage as it can and there is a point when it can't charge any more which I don't think anyone with a 5 amp electric motor for a water pump has to worry about.

#20

Your alternator will work harder internally to put out the same voltage when a load is placed on it. It doesn't make your engine work harder. It supplies as much voltage as it can and there is a point when it can't charge any more which I don't think anyone with a 5 amp electric motor for a water pump has to worry about.

#21

that is all very good information. I actually didn't know that about the high/low fan but as far as the electric water pump... I like to use the KISS rule. keep things simple stupid. I am certified with electronics and using the electric waterpump even if a second battery is used with a load handling switch.. would seem like a better choice to me then somthing else mechanical that has nothing to do with my valvetrain interfering with it. I would rather work with an electrical issue then deal with a mechanical pump that is known to rob power. Mechanical robs power and electrical doesn't. If the electrical system needed so much juice and couldn't provide it... it would drop the voltage in the whole system. Like you said power can't be created from no where. the engine runs the alternator but it can only handle so much before the voltage just drops off when too much amperage is being pulled through... As long as it never got to that point... the electric motor would easily run off the power that is always available in our cars. it isn't enough to demand so much that it would hurt anything and if it did a lot... maybe the laternator would burn up..? not sure... but they do make those 140 amp alternators right!!  I wish they weren't so pricey!

I wish they weren't so pricey!

I wish they weren't so pricey!

I wish they weren't so pricey!

#22

that is all very good information. I actually didn't know that about the high/low fan but as far as the electric water pump... I like to use the KISS rule. keep things simple stupid. I am certified with electronics and using the electric waterpump even if a second battery is used with a load handling switch.. would seem like a better choice to me then somthing else mechanical that has nothing to do with my valvetrain interfering with it. I would rather work with an electrical issue then deal with a mechanical pump that is known to rob power. Mechanical robs power and electrical doesn't. If the electrical system needed so much juice and couldn't provide it... it would drop the voltage in the whole system. Like you said power can't be created from no where. the engine runs the alternator but it can only handle so much before the voltage just drops off when too much amperage is being pulled through... As long as it never got to that point... the electric motor would easily run off the power that is always available in our cars. it isn't enough to demand so much that it would hurt anything and if it did a lot... maybe the laternator would burn up..? not sure... but they do make those 140 amp alternators right!!  I wish they weren't so pricey!

I wish they weren't so pricey!

I wish they weren't so pricey!

I wish they weren't so pricey!

#23

it would be more simple even if there was some kind of mod to bolt on to have a dual impellar to save energy. the camshaft driven waterpump is just an lt1 thing. It isn't efficient by technological standards. You can keep it.

#24

I'll stick to my mechanical wp so me or my wife don't get stuck in the wrong part of town with a completely usless wp.

#25

Your alternator will work harder internally to put out the same voltage when a load is placed on it. It doesn't make your engine work harder. It supplies as much voltage as it can and there is a point when it can't charge any more which I don't think anyone with a 5 amp electric motor for a water pump has to worry about.

Using your theory, as long as a very large alternator was pumping out 12V, it could produce a huge number of amps, taking zero power off the engine. Do you seriously believe that?

Normally at this point, I would say leave the mechanical issues alone, stick to the electrical ones.... but I don't think you should be arguing those either.

#26

The E-WP makes more power to the wheels, is less hassle, one lasted twice as long as two GM mechanicals, and made my lower cost Cloyes Double roller install with ease. That's what matters to me.

-Dustin-

-Dustin-

#27

Your alternator will work harder internally to put out the same voltage when a load is placed on it. It doesn't make your engine work harder. It supplies as much voltage as it can and there is a point when it can't charge any more which I don't think anyone with a 5 amp electric motor for a water pump has to worry about.

The EWP outlasting two GM pumps here would be the exception and not the rule IMHO. Less hassle, there are many things like wiring, failure circuit, fuses relays to deal with when using the EWP, the GM pump just bolt the damn thing on. Sorry but just cant agree hat the EWP is less hassle.

#28

The EWP outlasting two GM pumps here would be the exception and not the rule IMHO. Less hassle, there are many things like wiring, failure circuit, fuses relays to deal with when using the EWP, the GM pump just bolt the damn thing on. Sorry but just cant agree hat the EWP is less hassle.

Everyone else can do what they want, but for me the $135 CSR E-WP was one of my best upgrades. Great return on my investment.

-Dustin-

Last edited by Bersaglieri; 06-30-2007 at 10:13 PM.

#29

As mentioned, the EWP will not flow enough under load for certain applications...From a previous post I have made

The alternator is converting mechanical energy to electrical energy. The alternator may have a max of 140 amps, but the amount of current actually produced depends on the load. The alternator actually just provides a voltage, and the current = the voltage/impedance. The more the load, the more the current. Power = voltage * current so 20 amps * 12 volts = 240 watts. 240 watts /746 = .3hp to turn the alternator (excluding losses.)

Now, an electric motor is supplied with a constant voltage. The motor will pull as much current as needed to keep turning at a constant speed. As the load increases, the current will increase until the max value (limited) if the current is not sufficient, the motor will slow down and pump less water.

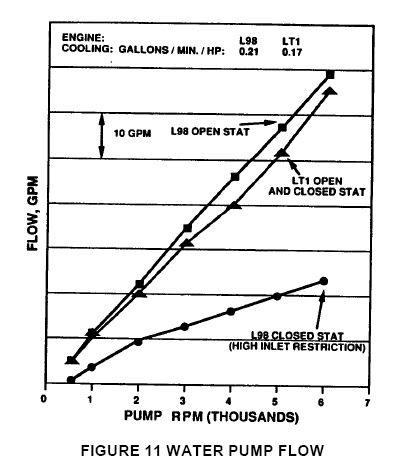

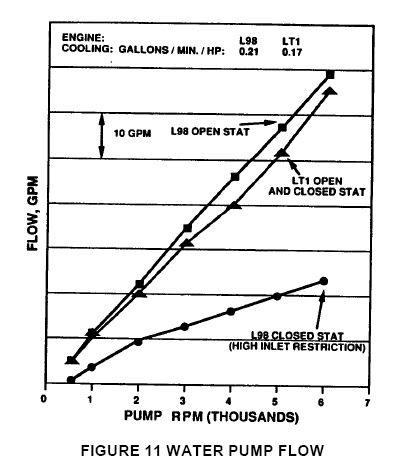

Here is a graph of the volume of the stock pump. Do you think a small electrical motor can flow this much under load?

The alternator is converting mechanical energy to electrical energy. The alternator may have a max of 140 amps, but the amount of current actually produced depends on the load. The alternator actually just provides a voltage, and the current = the voltage/impedance. The more the load, the more the current. Power = voltage * current so 20 amps * 12 volts = 240 watts. 240 watts /746 = .3hp to turn the alternator (excluding losses.)

Now, an electric motor is supplied with a constant voltage. The motor will pull as much current as needed to keep turning at a constant speed. As the load increases, the current will increase until the max value (limited) if the current is not sufficient, the motor will slow down and pump less water.

Here is a graph of the volume of the stock pump. Do you think a small electrical motor can flow this much under load?