by request new thread, hope this helps guys

#1

by request new thread, hope this helps guys

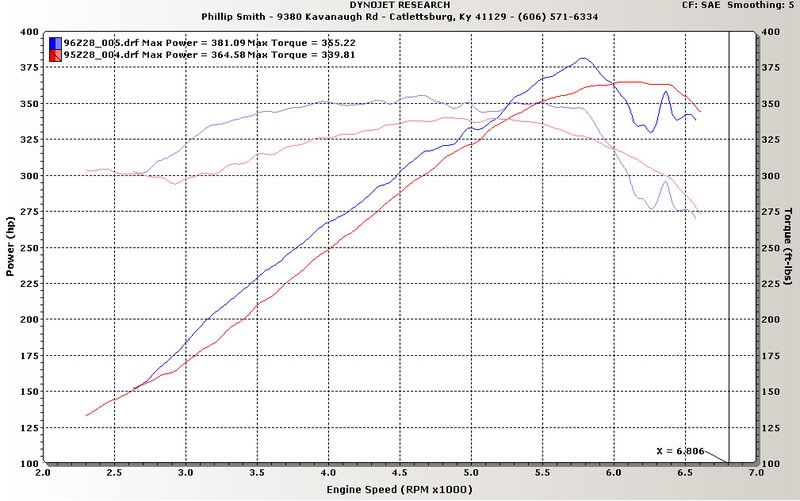

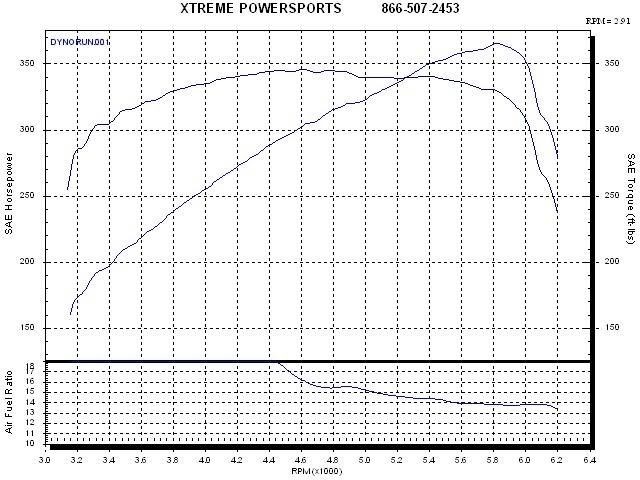

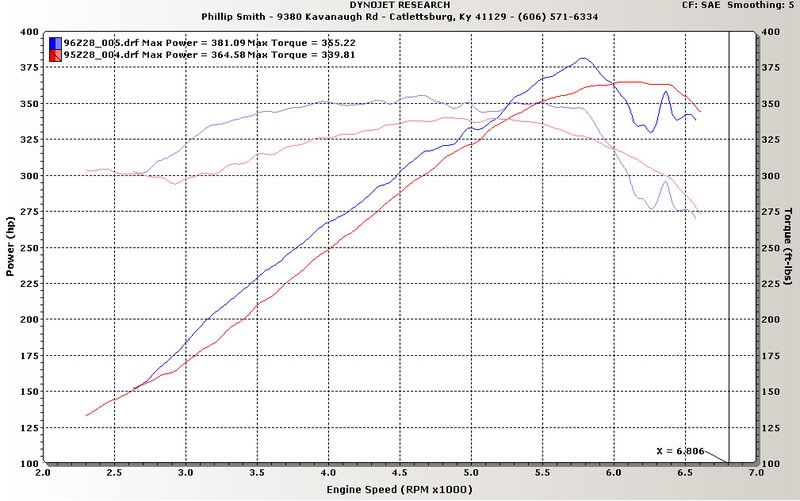

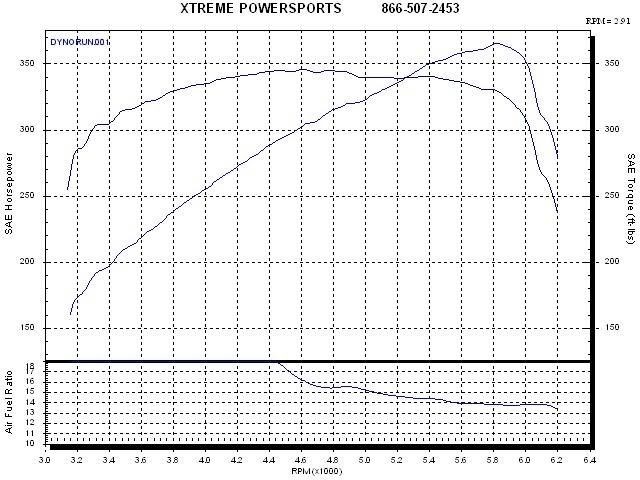

ok, my signature has whats been done to the car, the problem is this back in December we had my car dyno tuned, on the dyno my car made 381 rwhp and 355 fptq, which I thought was great, but we got looking at the graph and the car pulled like a mother to 5900 rpms, then would just fall straight off....the car would float the valves, so I emailed Bret Bauer, and he said that the springs were set-up on the wrong install height of 1.80, he wanted them on a 1.75 install height, I was going to change the springs to Patriot extremes 8501-BSBC, but Bret asked me not to do that, he said he would send me another set of springs if I would, re-install them at the correct height and spring pressures, Bret even talked to the guy that did that change......well last Friday I had the car re-dyno, yes it was on a different dyno, but this dyno was supposed to read higher than the one before, but anyways, the car pulled hard just like before, but would float out again at the very same place, but this time it only dynoed 365 RWHP and around 350 FPTQ, but the graph was almost the same for the dropout point right at 5900 rpms. So i sent the dyno sheets to Bret and the other guy that tuned the car before. Bret's asked some simple questions, what size rockers, lifters, and pushrods, so i told him 1.6 rr, stock lifters and then the pushrods were 8308-16 hi-tech 5/16" 7.450" oil restricting from Comp, Bret thinks they are too long and is causing a problem......me I have no ideal.....I am not trying tom step on anyones toes or anything like that, I just want my car fixed and for it to perform like they said it would, do you blame me for that, I have included both dyno graphs in this post also........

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

#3

Dan I know, and I agree, but Eric Carey is taking a fit and says its right, he says it checked and double checked it, he thinks it doesn't have enough spring pressure and wants the Patriot extreme 8501-BSBC put in there, me I have no ideal what to do, all I know is I have spent a hell of alot of money and the damn thing still won't pull to 6300 like Bret said it would, and thats as far as I wanted to pull it, at least no farther than 6500, with a stock short block with 107, 000 plus miles and stock lifters and rings......, I am already taking a chance there alone......

#4

#7

#8

yeah thats what i am getting at, i have a similar set up and needed 7.150, but you need to measure yourself, but not that guy eric. dont go back to him yet

#10

"There was no shortblock work done. We even reused the stock lifters. And yes i know .042 is a lot of milling but lt1 chambers suck *** so i had to redo them. I milled the first part of that wierd quench pad all the way out, if you look on lingefelters page they dont have one at all so i'm assuming they do even more milling. It's not an uncommon practice at all.

The chambers are about 54cc's, and it has a .027 gasket. If i can remember correctly it's got around 11.3:1 or so but i can't remember for sure unless i calculate it up again." posted by Eric on kyhorsepower.com

The chambers are about 54cc's, and it has a .027 gasket. If i can remember correctly it's got around 11.3:1 or so but i can't remember for sure unless i calculate it up again." posted by Eric on kyhorsepower.com

#13

#14

When you mill the heads that means that pushrods need to be shorter. Stock length is 7.20" so 7.45" is going to be too long no matter how you measure it. The curve on the first graph in the red looks good. What is that from? The air fuel in the second graph is way lean and who knows on the second. What tuning is being done?